A regular quick check of your kit helps to ensure that it’s ready when you need it…

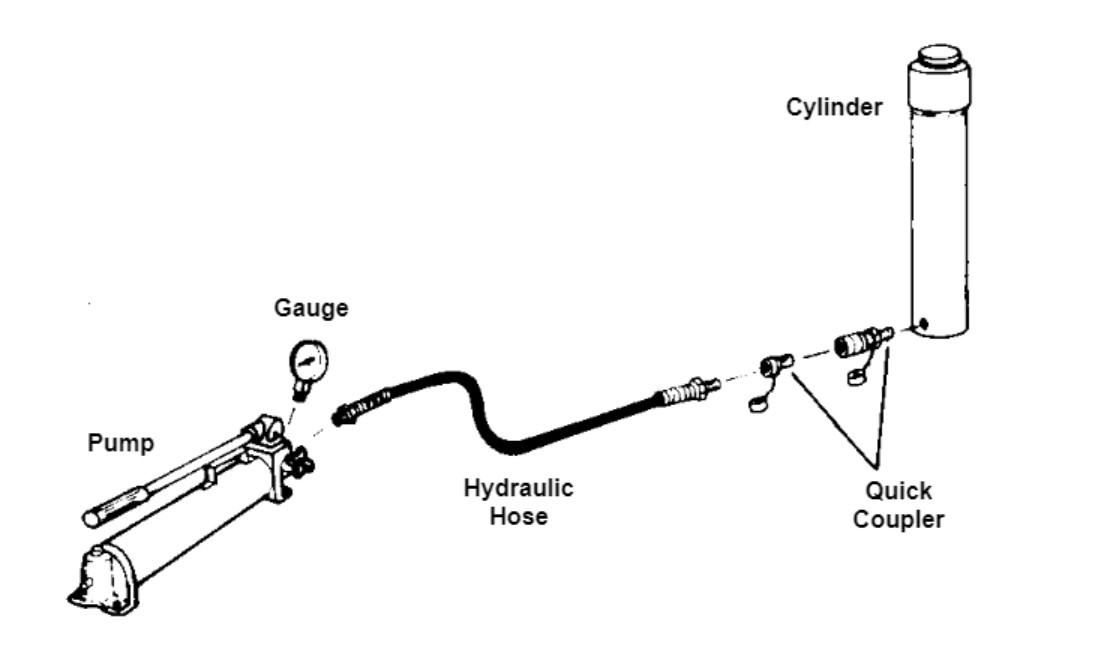

If you’ve got a single-acting kit or porta power kit like this, it’s important to regularly check that each of the components is in good working order and that the system is functioning properly.

We recommend connecting the system (as per the diagram below and as outlined in your operating instructions) at least every 6 months to perform a basic system check.

Check that all kit components are present and appear to be in good order. If there are any signs of the following conditions, DO NOT attempt to connect the system and pressurise the cylinder.

- Cracked or damaged cylinder

- Excessive wear, bending, damage, or insufficient thread engagement

- Leaking hydraulic fluid

- Scored or damaged piston rod

- Improperly functioning swivel heads and caps

- Loose bolts

- Damaged or improperly assembled accessory equipment

- Modified, welded, or altered equipment

- Bent or damaged couplers, port threads or hoses

If all components are present and in good working order, attach the cylinder to the hand pump via the quick coupling hose attachments. There is no need to operate under load, just cycle through extending and retracting the ram.

- Always use clean, approved hydraulic fluid and change as needed.

- Any exposed threads (male or female) must be cleaned and lubricated regularly and protected from damage.

- If a cylinder or ram has been exposed to rain, snow, sand, grit-laden air, or any corrosive environment it must be cleaned, lubricated, and protected immediately after exposure.

- If the cylinder or ram condition suggests damage or if the hose shows any sign of damage do not attempt to operate the system.

** Important reminder – high-pressure hydraulics can cause serious injury if used incorrectly so always refer to the manufacturer’s safety and operating instructions.

For more information on preventative checks and maintenance, simply call our team on 1300 BOSS HYD or email sales@bosshydraulics.com.au